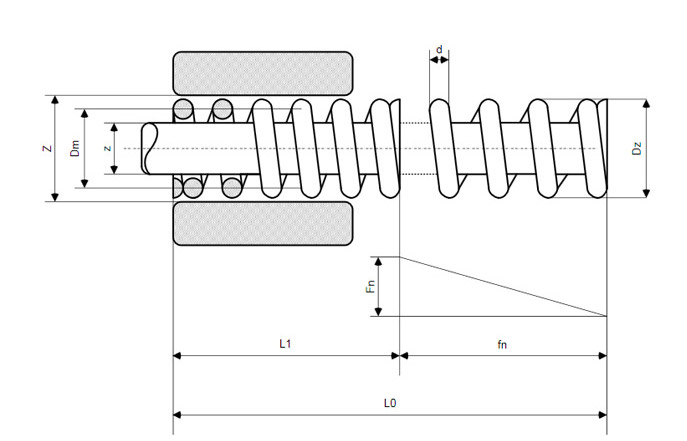

d – wire diameter

Dm – spring pitch diameter

Dz – spring outer diameter

L0 – spring length in free state

n – active coil count

Ln – permissible pressure

Fn – force generated by the spring (N)

fn – deflection at maximum load

c – spring stiffness (N/mm)

K – socket diameter

k – pin diameter

Stainless steel = 0.833 x spring steel

1kg = 9,81N

1N = 0,102kg

Material:

carbon spring steel 51 Crv4

chrome-nickel stainless steel 1.4310

Compression springs manufactured at our plants

are used in many industries as components for carrying small as well as large loads. The continuous process of spring design forces us to constantly develop our machinery. So as to meet the applications of each spring in the creation of modern machines of our customers.

We manufacture compression springs from quality rods such as:

- Carbon spring material 51Crv4, 51Crv4

- Stainless chrome-nickel material 1.4310, 1.4301

Rod diameters for the production of springs in the field of compression springs are divided into two production lines. Compression springs in the first production line are rolled on machines in a range of materials with a rod cross-section of 0.40 mm to 20 mm. The compression springs created on the second production line are much larger springs with a rod cross-section of 21 mm to 48 mm.

As an interesting fact, we would like to mention that the largest compression spring that was made in our plant weighed 94 kg, and a several-meter-long spring rod was used in the manufacture of the spring. All compression springs leaving our production have material approvals, certificates of conformity and full characteristics made on a sample of springs from the corresponding batch. The main recipients of our springs are the railroad, power and machinery industries. We are a well-recognized spring manufacturer in the above industries due to our certification during the spring manufacturing process. We can submit the compression springs for characterization at our facility and plot charts of the tests performed.

What distinguishes our compression springs from the competition?

- High spring strength due to the use of certified materials and years of experience in the manufacturing process.

- High quality standards during the production of each spring.

- Pressure springs are issued 3.1 quality certificates.

- Short lead times.

- Full process of spring production under the control of specialized employees in the field of machine operation and spring processing.

Please also visit our spring catalogs page where you can find the right compression springs.

All above compression springs are available from stock or within 7 working days. If customers are interested in customized compression spring size, please feel free to contact us by phone or send your inquiry to biuro.fedratech@gmail.com. An offer for compression springs will be prepared with a preliminary calculation of spring forces within 24H.